SCHUMACHER Elektromechanik GmbH specializes in customer-specific production of electronic components with a focus on power supplies for lasers in industrial and scientific applications. On top of that, electrical goods can be specially developed and produced for innovative applications on request.

Our experts from the mechanical department contribute significantly to a quick and reliable realisation of custom-made products. In this department we produce custom-fit detailed solutions such as punched sheet metal, special bores, special tools and separate production structures when required. Postprocessing, for example bends, cuts, bores and threads, which are required for our special applications, can also be carried out here.

Production

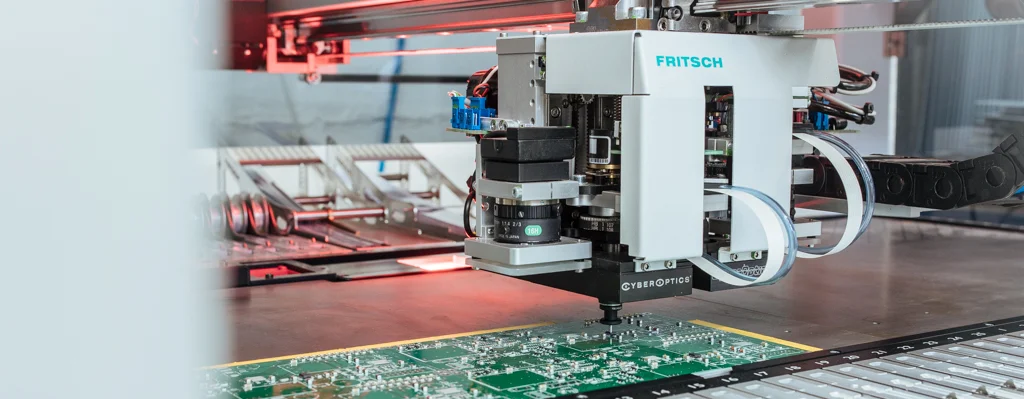

SMD assembly

Surface mounted devices are a specialty of SCHUMACHER Elektromechanik GmbH. We produce fully assembled printed circuit boards in SMD technique and Mischtechnik (mixed technique). And in order to produce complex layouts in a short time, we have two state-of-the-art placement machines with Dispensor and AOI systems at our disposal. Further services we provide are chip-on-board assembly and double-sided assembly of multilayer, rigid-flex and flexible circuit boards.

The SCHUMACHER Elektromechanik Competency Plus

- PCB sizes up to 330x380 mm, max 800x500 mm

- Components from 0402 to 50x50 mm edge length

- µBGAs

- Vapor phase soldering bath

- Process is leaded or RoHS compliant

- Automatic Optical Inspection (AOI)

- Dispensor for small batches

THT assembly

For applications that cannot be covered by SMD production, we can produce fully assembled printed circuit boards in THT technique and Mischtechnik (mixed technique) with the help of state-of-the-art automatic placement machines and flow soldering stations. We also offer a selective soldering system for medium and large-scale production.

Many of our production steps are automated. There are however always individual tasks that need to be precision-crafted by hand. These special soldering operations are carried out by our experienced employees at special, calibrated soldering workstations. This allows quantities to be flexible and customer requests for changes to be implemented quickly.

The SCHUMACHER Elektromechanik Competency Plus

- Single and double placement

- Large circuit boards up to 400x450 mm

- Soldering in double wave soldering machines (RoHS-compliant)

- Selective soldering machine

- Press-fit technology from different manufacturers

The SCHUMACHER Elektromechanik Competency Plus

- Many years of experience

- cost-optimised design

- holistic mechanics development

- SolidWorks 3D product preview

- High technical quality

Cable assembly

Cable harnesses are the inner nerve cords of a device. They must meet the different electrical requirements (heat, high voltage, screen for interfering signals in the high frequency range, fast switching speeds) and guarantee the transmission of digital signals for the control of IT-components, high voltage transmission lines, particularly for wiring of laser components.

We manufacture single strands and cable harnesses as well as complex cables for high-quality components.

In addition to a modern strand cutting machine, we have two crimping machines as well as all the machines and manual tools to match the contacts we use. We manufacture special components in-house and by hand.

The SCHUMACHER Elektromechanik Competency Plus

- Wiring harnesses, cable harnesses, plug connections

- High quality through in-house production

- Machine and manual production

- Special testing station

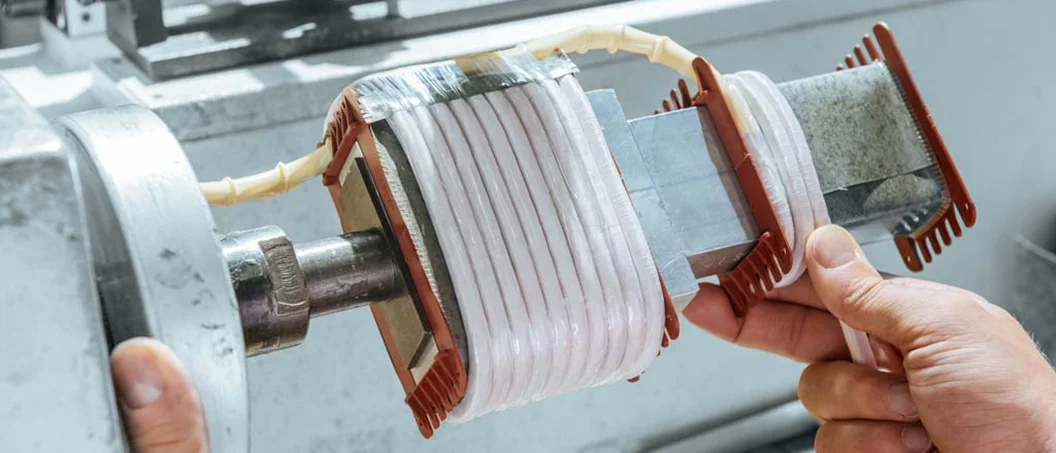

Specialised transformer manufacturing

Specialised transformer manufacturing has been the core of SCHUMACHER Elektromechanik GmbH for decades. In particular, producing hand-made transformers in the laser and high-load range, is one of our strong points. This includes manufacturing of standard and special ferrite winding components, as well as vacuum capping for winding elements with resin and lacquer, and the heat treatment afterwards. We also carry out separation voltage tests up to 100,000 volts in our in-house test room.

The SCHUMACHER Elektromechanik Competency Plus

- Standard and special ferrite transformers

- Hand-made transformers

- Transformers in the laser and high-load range

- Vacuum capping

- Isolation voltage tests up to 100,000 volts

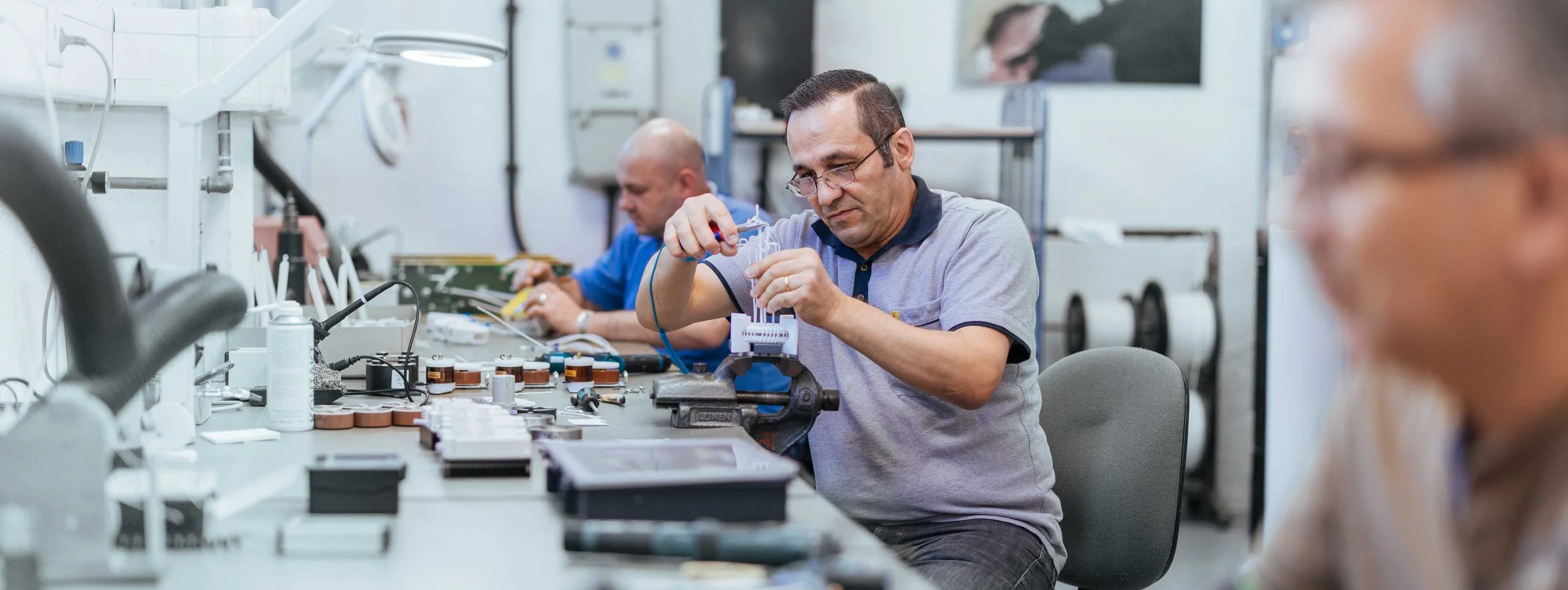

Final assembly

In the final assembly, printed circuit boards, manufactured cables and bought-in components are combined to form the end products. With many devices, especially if they are only made in small batches, this cannot be done by machine. At SCHUMACHER Elektromechanik GmbH, qualified employees also meet the high quality requirements associated with laser technology when they are working by hand at specially equipped workstations.

Specially trained assembly teams for specific products or product groups make short-term production possible, even in small quantities.

Thanks to short distances between workstations, final testing can often take place close to production. Any errors can then be identified and repaired immediately.

The SCHUMACHER Elektromechanik Competency Plus

- High-quality assembly

- Fast small-batch production

- Special teams for individual products

- Final testing